Tech Students Construct News Anchor Desk for the Courier

May 23, 2023

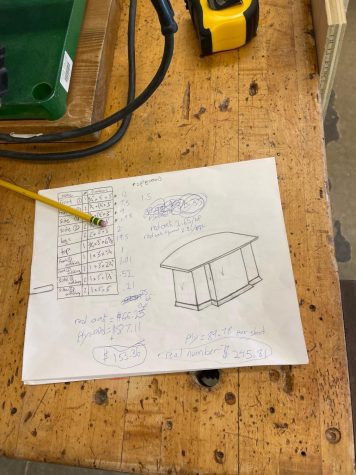

With $1000 in the bank to update the TV studio, the Courier decided they would replace the current royal red felt cloth taped on a folding table and spend it on a real anchor desk.

After receiving the Innovation Grant from the Southern York County Foundation to redesign the set for the Courier Daily News, the Courier knew who they wanted to ask current wood technology students to build the piece.

Technology education teacher Shane Waters tasked his students with creating a news anchor desk from scratch.

Co-advisor of the Courier, Tim Hare, did have some ideas in mind when it came to the desk, which he shared with the students.

“Mr. Hare brought us a design saying he wanted a new desk for the new studio… and then one of our students took them and came up with his own working plan of it,” Waters said.

After some ideas were shared, wood tech student Ryan Thomas said that it was then up to them to do the rest.

Thomas said that the project was “100 percent” student-led.

“We had some assistance from Mr. Waters, but very minor,” Thomas said.

Since the students had never built an anchor desk before, there were some adjustments that they had to make to their building process.

“It requires teamwork because certain parts of the project you can’t just do by yourself…” Thomas said.

Another student who worked on the desk senior John Johnson added that “it was harder because it was one of our biggest projects of the year… so it took a lot of space,” and that it “put the machines to their limit.”

Thomas explains that their biggest challenge while building the desk was just how big it was.

“Our planer and joiner and table saw are only so big,” Thomas said.

This meant that they had to make the desk big enough for its purpose, but also small enough for the machines.

Apart from the size of the machines, another challenge the students faced was the size of doors throughout the school, according to Johnson.

“It had to be able to fit through the [school] doors, so our maximum width was 36 inches,” Johnson said.

Not only did this project require teamwork within the wood tech class, but it also required the assistance of the metal shop class.

The wood alone was not strong enough to ensure the desk wouldn’t collapse.

“We ended up having to bring in metal tech into it as well to create a bracket system,” Waters said.

The bracket system was a way of giving the desk more structural support.

After all is said and done, Waters is proud of what his students were able to accomplish.

“It was like a well-oiled machine, from start to finish,” Waters said. “Even the challenges we ran into, we solved within a class period.”

Hare expressed his satisfaction with the students’ job.

“I’m incredibly thrilled…This is something that we have wanted for a very long time.”